ENGINEERING | FEA TESTING

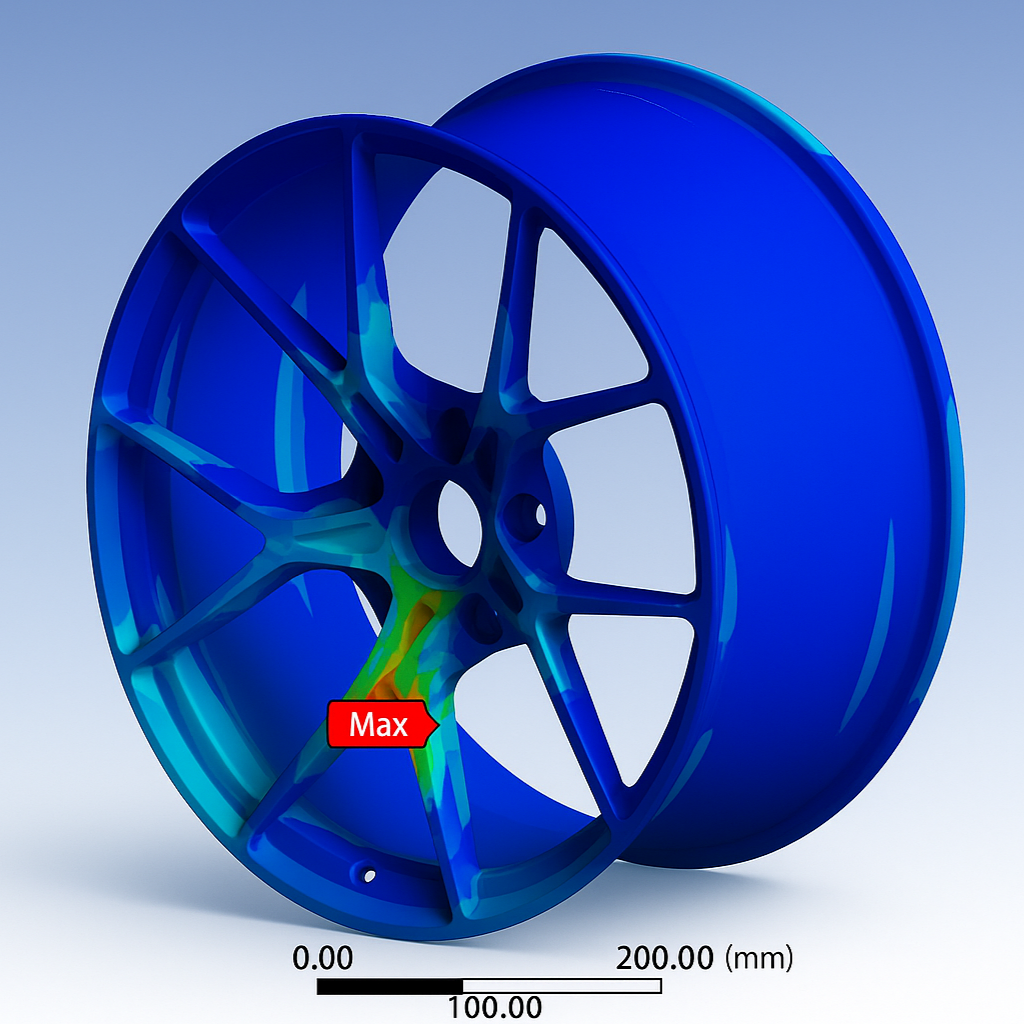

Each set of Project 12 Wheels are meticulously designed, engineered, and crafted in our Southern California Facility. Our team at Project 12 Wheels with over 15 years of combined forged wheel experience allows us to have full control over the quality of our process. Each order goes through Finite Element Analysis (FEA) testing to ensure the most optimal combination of lightweight, durability, and strength.

In-House Forging

Crafted on our state-of-the-art 10,000-ton forging machine, these blanks are compressed with immense force to achieve unmatched grain structure and material strength. This in-house process ensures every wheel begins with the highest quality foundation.

Milling

Once the profile is completed, the forgings are then turned over to the mill process. The mill process is where the design comes to life. As mill cycles run through a series of pre-selected tool sets and milling paths that can take up to 8 hours per wheel to achieve the utmost precision.

After the milling process is completed, each section of raw milled aluminum needs to go through many stages of Hand Filing, Deburring, Buffing and Ceramic Bead High-Luster Polishing before it is ready for its ultimate finish. This is a vital stage for our craftsmen to prep each wheel before its coating. After each wheel is filed and sculpted the wheels go through a detailed check list with zero compromises.

Prep & Finishing

The most rewarding part of the manufacturing process is the finish stage. Project 12 Wheels premium finish line offers a brushed or polished base paired with transparent powder coats to reveal the beauty and details in the design. At Project 12 Wheels we are always learning new ways in achieving the utmost beautiful finishes in our industry.

Each component of the wheel is offered with a Gloss, Satin or Texture finish of your choice.